Due to graphite’s remarkable thermal properties, graphite is an excellent material to consider when doing vacuum furnace applications.

This is mainly attributed to the material’s innate ability to transfer heat. Graphite has an incredibly high melting point, and technically does not melt but sublimates into a gas at a certain number of atmospheres. Graphite materials also exhibits minimal expansion when heated, which makes it quite suitable for vacuum furnace applications.

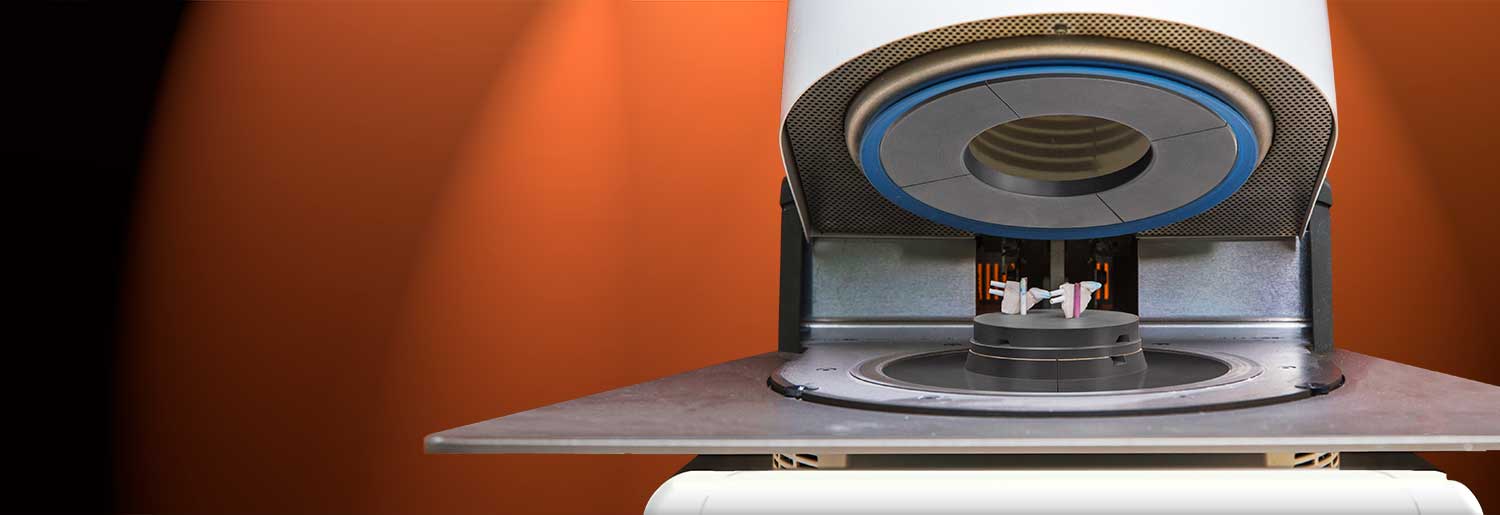

As a result, graphite materials are frequently used to make trays, racks, shelving, baskets, carrier systems, and even various holders or fixtures for heat treating, brazing, and sintering applications. For these particular applications, a high thermal conductivity and low CTE [coefficient of thermal expansion] are typically required, and Ohio Carbon Blank offers several materials that fit that criteria.

Via a print or solid model, we can custom manufacture products to your desired specifications, and we have specialty graphite materials for these particular applications. Upload your drawings or solid models and get a quotation from Ohio Carbon Blank today!

- Heat Treating

- Brazing Applications

- Sintering Applications

- Welding Applications

- Graphite Fixtures

- Vacuum Furnace Parts