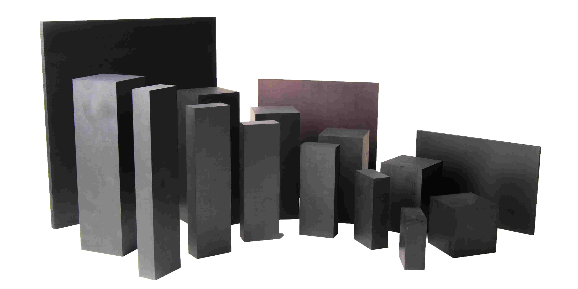

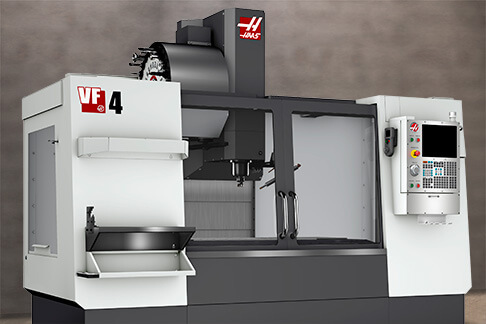

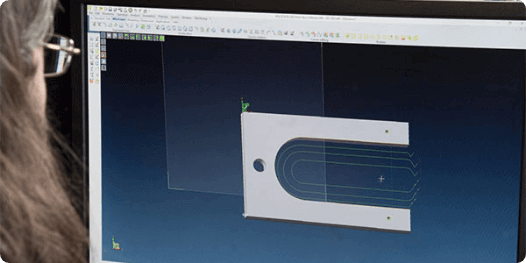

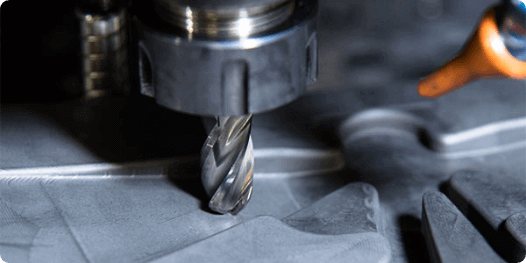

From prototyping to on-demand production, our in-house engineering and quality assurance teams have the capabilities to machine custom graphite products to exact specification.

CNC Graphite Machining

Graphite CNC Machining services for your prototypes and high-volume production

Request a Quote

.png)